| Topics | Sections |

|---|---|

| OVERVIEW | 12.1 What is the purpose of this chapter? 12.2 What is the Service policy for using chain saws? 12.3 What is the scope of this chapter? 12.4 What are the authorities for this chapter? 12.5 What terms do you need to know to understand this chapter? 12.6 Who is responsible for the safe operation of chain saws? |

| CHAIN SAW TRAINING AND OPERATING REQUIREMENTS | 12.7 What are the training requirements for chain saw operation? 12.8 How does the Service classify chain saw operators, and what do those classifications mean? 12.9 What does the Service use to show that an employee has authorization to use a chain saw? 12.10 What are the general operational requirements for chain saw operators? 12.11 What are the requirements for instructors who teach the S-212 non-fire course? 12.12 What are the equipment specifications for chain saws? 12.13 What are the standards for PPE and its maintenance? 12.14 What PPE must operators use? 12.15 What other requirements do chain saw operators have to follow? |

OVERVIEW

12.1 What is the purpose of this chapter? This chapter describes the U.S. Fish and Wildlife Service (Service) requirements and responsibilities for providing equipment and training that will protect you from hazards you may encounter while using a chain saw.

12.2 What is the Service policy for using chain saws? Our policy is to prevent occupational injury, illness, or property damage associated with use of chain saws by establishing safe and effective procedures and controls to guard against and minimize mishaps.

12.3 What is the scope of this chapter?

A. This chapter covers the use of chain saws for non-fire operations by Service employees, volunteers, and partners working on Service-owned or managed land.

B. This chapter does not cover:

(1) Contractors. Contractors must comply with the safety and health clauses in their contract agreements and with Federal, State, and local requirements; or

(2) Service fire management operations. We describe the requirements for Service fire management operations in a separate Service safety chapter (see 621 FW 1).

C. There are additional requirements associated with mobilization of employees to non-fire incidents (e.g., hurricanes, tornados) to function as chainsaw operators that are not covered in this chapter, such as physical fitness requirements. (See the Department of the Interior Incident Positions Qualification Guide and the Service Incident Response Implementation Guide.)

12.4 What are the authorities for this chapter?

A. American National Standards Institute (ANSI) Standard B175.1, Safety Requirements for Gasoline-Powered Chain Saws.

B. Basic Program Elements for Federal Employee Occupational Safety & Health Programs and Related Matters (29 CFR 1960).

C. Executive Order 12196, Occupational Safety and Health Programs for Federal Employees.

D. Occupational Safety and Health Act (of 1970) Federal Agency Safety Programs and Responsibilities (Public Law 91-596, Sec. 19).

E. Occupational Safety and Health Administration (OSHA) Standards, Occupational Safety and Health Standards (29 CFR 1910).

F. OSHA Standards, Logging Operations (29 CFR 1910.266).

G. OSHA Standards, Safety and Health Regulations for Construction (29 CFR 1926).

12.5 What terms do you need to know to understand this chapter?

A. Brushing: Removing brush and shrubs to clear out an area. Cutting tree and brush material that is less than 8 inches in diameter and less than 10 feet in height.

B. Bucking: Sawing trees and limbs into shorter lengths.

C. DBH: Diameter of a tree at breast height (4½ feet above ground level).

D. Escape route: An “escape path” and an “alternate path.” Each path should lead diagonally away from the expected felling line (forming a 45-degree angle between the two clear pathways) directly into the safe zone.

E. Faller: A person authorized to fell trees.

F. Felling: Cutting down trees and brush materials that are over 10 feet tall or greater than 8 inches in diameter, or both.

G. Limbing: Removing the branches from a felled or standing tree.

H. Safe zone: An area away from the tree you plan to fell and in the quadrant opposite the planned fall direction of the tree. The escape path and the alternate path lead to the safe zone.

I. Sawyer: An authorized chain saw operator who limbs, bucks, and fells trees.

12.6 Who is responsible for the safe operation of chain saws? Table 12-1 shows who is responsible for Service chain saw safety.

Table 12-1: Responsibilities for Chain Saw Operations

| This official... | Is responsible for... |

|---|---|

| A. The Director | (1) Ensuring the Service maintains an effective and comprehensive occupational safety and health program, and (2) Approving our chain saw safety program policy. |

| B. The Assistant Director - Business Management and Operations | (1) Ensuring we have an effective chain saw safety program, and (2) Providing sufficient support and resources to the Chief, Division of Safety and Health, to ensure that the Chief can effectively accomplish program goals. |

| C. Regional Directors and the Director, National Conservation Training Center | Ensuring there are sufficient resources and support in place to implement an effective and comprehensive chain saw safety program within their areas of responsibility. |

| D. The Chief, Division of Safety and Health | (1) Revising and updating this chapter, as necessary, and (2) Interpreting the requirements in this chapter and resolving Servicewide issues and questions about our chain saw safety program. |

| E. Regional Safety Managers | (1) Advising Project Leaders/Supervisors/Facility Managers and Collateral Duty Safety Officers on the implementation of our chain saw safety program in their Regions, (2) Interpreting program requirements and resolving Regionwide issues and questions, (3) Reviewing workplace assessments and advising Project Leaders/Supervisors/Facility Managers to help them determine the need for chain saw safety, and (4) Providing guidance to Project Leaders/Supervisors/Facility Managers on the following: (a) Using engineering or administrative controls when workers are, or may be, exposed to chemical, physical, or biological hazards at or above established permissible exposure limits or threshold limit values when using saws on the job; (b) Buying and using Personal Protective Equipment (PPE) when engineering and administrative controls are not adequate (see section 12.13 and 241 FW 3); and (c) Evaluating the management of chain saw use, training, and PPE during field station safety program evaluations. |

F. Project Leaders/Supervisors/ Facility Managers | (1) Ensuring personnel who perform chain saw operations: (a) Comply with this chapter when using chain saws on the job; (b) Take training and are current in Cardiopulmonary Resuscitation (CPR) and standard first aid as required by a recognized certification program such as those the American Red Cross, American Heart Association, and National Safety Council sponsor; (c) Qualify through training and experience to perform their particular function related to chain saw operations; and (d) Do not exceed their authorization or experience level when operating a chain saw; (2) Entering information showing employees’ completion of chain saw training, including refresher training, into the Department’s Learning Management System (i.e., DOI Learn); (3) Issuing and, if necessary, revising or revoking chain saw authorization; (4) In conjunction with a competent operator, preparing a Job Hazard Assessment (JHA) (see 240 FW 1). The JHA must include tasks that will be performed, associated hazards, and required PPE for personnel subject to this policy; (5) Providing the necessary PPE (see section 12.13); (6) Providing access to medical service providers for those employees who get sick or experience ill effects from working with or being exposed to workplace hazards. We provide these medical services at no cost to the employee. Medical coverage must be consistent with the Federal Employees’ Compensation Act (see 242 FW 4); (7) Including appropriate personal exposure sampling data in employee medical files. Appropriate sampling data is information we collect to comply with OSHA regulations (e.g., audiograms [see 242 FW 3]); (8) Ensuring storage, inventory, and physical inspection of chain saws and chain saw support equipment are, at a minimum, included as part of the facility inspection cycle; and (9) Ensuring Safety Data Sheets (SDS, formerly MSDS) are available for each product used in association with chain saw operations. |

| G. Contracting Officers | Ensuring that any contracts for chain saw operations or chain saw-related materials contain the appropriate safety clauses and meet Federal, State, and local requirements. |

| H. Employees | (1) Complying with this chapter when working with chain saws; (2) Successfully completing and maintaining current CPR, standard first aid, and chain saw training and training documentation specific to their responsibilities; (3) Wearing and maintaining PPE to reduce or eliminate potential workplace exposures; (4) Notifying their Project Leader/Supervisor/Facility Manager if they are experiencing any adverse health effects; (5) Not eating, smoking, or drinking in or near the work area where chemicals, hazardous materials, or chain saws are stored, transported, or used; (6) Using every reasonable precaution to ensure the safety and security of other personnel and the general public; (7) Immediately reporting to their Project Leader/Supervisor/Facility Manager any theft or loss of chain saws or related equipment; and (8) Regardless of their experience or qualifications, when preparing to use a chain saw, considering all the factors of the job to determine if the level of risk is acceptable. If the level of risk is not acceptable, the operator has the authority and responsibility to walk away. |

TRAINING AND OPERATING REQUIREMENTS

12.7 What are the training requirements for chain saw operation? All Service employees who may use chain saws as part of their duties must take training and demonstrate proficiency before they operate a chain saw.

A. Chain Saw Course Requirements:

(1) New operators:All new Service chain saw operators must take the S-212 Wildland Fire Chain Saws course or approved alternative chain saw course (see subsection 2(b) below) within 6 months of employment.

(a) During the 6-month interim period, new Service chain saw operators may operate chains saws if they:

(i) Have experience,

(ii) Can demonstrate their capabilities to an intermediate or advanced sawyer, and

(iii) Work under the direct and observed supervision of an intermediate or advanced sawyer.

(b) The Project Leader/Supervisor/Facility Manager must sign the Chain Saw Operator Authorization Form (FWS Form 3-2412) before the new operator may use the chain saw.

(2) Details about S-212 and Alternative Courses:

(a) The S-212 Wildland Fire Chain Saws course that non-fire chain saw operators take may include only the portions appropriate to non-fire duties. Non-fire operators do not have to meet the S-212 prerequisites, such as Firefighter Type 2, S-130 (Firefighter Training), and S-190 (Introduction to Wildland Fire Behavior).

(b) The Project Leader/Supervisor/Facility Manager and the Regional Safety Manager must approve, in advance, requests for alternative training to the S-212 Wildland Fire Chain Saws course. An approved alternative chain saw course must, at a minimum, meet all of the criteria of the S-212 course and its qualification task books, with the exception of fire-related duties. Training field exercises must include Basic Faller practice appropriate for non-fire duties (see Table 12-3).

B. Annual Chain Saw Refresher Training: All authorized chain saw operators must complete RT-212 Annual Chain Saw Refresher Training, as described in Exhibit 1. Project Leaders/Supervisors/Facility Managers must keep refresher training documentation in the employee’s training records.

12.8 How does the Service classify chain saw operators, and what do those classifications mean?

A. The Service recognizes three levels of chain saw operator that mirror the wildfire chain saw operator qualifications developed and maintained by the National Wildfire Coordinating Group (NWCG). See Table 12-2.

Table 12-2: Service Chain Saw Qualification Crosswalk

| Service Qualifications (non-fire) | NWCG Qualifications (wildland fire) |

|---|---|

| Basic Faller | (FAL3) Basic Faller |

| Intermediate Faller | (FAL2) Intermediate Faller |

| Advanced Faller | (FAL1) Advanced Faller |

B. Project Leaders/Supervisors/Facility Managers must ensure that any employees who operate a chain saw are in compliance with Table 12-3, Service Chain Saw Skill Classification System (non-fire).

Table 12-3 Service Chain Saw Skill Classification System (Non-Fire)

| Faller Classification | Description |

|---|---|

| Basic Faller (low complexity) | An individual trained or evaluated at the introductory level for chain saw operations. These fallers have completed the S-212 (or equivalent training) classroom and field training for general saw work (such as cutting, brushing, and bucking, and the first basic steps in felling). ►Basic Fallers can fell, limb, and buck trees up to 8 inches DBH in a non-fire environment*. ► An authorized Intermediate or Advanced Faller must verify that a Basic Faller Trainee completed the tasks required for this position task book and perform the final evaluation for Basic Faller operations. ►Employees trained through the S-212 course or an alternative chain saw course without completing the faller position task book appropriate to non-fire duties must limit their activities to Basic Faller standards and work under the supervision of an Intermediate Faller. |

| Intermediate Faller (moderate complexity) | An individual who has been authorized as a Basic Faller and has demonstrated sufficient judgment, skill, and knowledge to be trained and authorized in moderately complex chain saw operations. They have demonstrated that they have the judgment to assess and decline assignments that exceed their skill level. ►Intermediate Fallers can fell, limb, and buck trees up to 24 inches DBH in a non-fire environment*. ► Those authorized as an Intermediate Faller may work independently on projects/assignments up to their level of skill. ► An authorized Intermediate or Advanced Faller must verify that an Intermediate Faller Trainee completed the tasks required for this position task book and perform the final evaluation. |

| Advanced Faller (high complexity) | An individual who has demonstrated judgment and proficiency in correctly handling complex sawing and felling in wildland fire operations. Advanced Fallers are approved to handle complex sawing and felling operations in non-fire environments. ► Advanced Fallers have no limit on tree size, yet retain the right that all chain saw operators have to walk away from a tree if a risk analysis warrants it. ► An authorized Advanced Faller must verify that the operator completed the tasks required for this position task book and perform the final evaluation. |

*DBH measurements are not the only determining factor in the complexity of tree felling operations. We expect chain saw operators to thoroughly assess each tree and determine the extent of qualifications required to safely perform a felling, limbing, or bucking operation.

12.9 What does the Service use to show that an employee has authorization to use a chain saw?

A. After successfully completing the S-212 course or an approved alternative chain saw operator training course, an authorized instructor will give the chain saw operator a signed certificate or other proof of course completion. The operator must provide this documentation to his/her/their Project Leader/Supervisor/Facility Manager. The Project Leader/Supervisor/Facility Manager must then complete the Chain Saw Operator Authorization Form (FWS Form 3-2412) and keep all the training documentation in the employee’s training records.

B. For a chain saw operator to be authorized as a Basic, Intermediate, or Advanced Faller:

(1) Chain saw operators in training (Trainee) must:

(a) Complete the NWCG chain saw position task book, which includes completing non-fire specific tasks and the requisite chain saw operator evaluation form and stump analysis form found in the position task book (see Exhibit 2);

(b) Have the position task book and evaluation forms filled out by qualified trainers and evaluators (see section 12.11); and

(c) Give the form to his/her/their Project Leader/Supervisor/Facility Manager.

(2) The Project Leader/Supervisor/Facility Manager must:

(a) Complete the Chain Saw Operator Authorization Form (FWS Form 3-2412); and

(b) Keep the training documentation, position task books, and requisite chain saw operator evaluation form in the employee’s training records.

(i) Employees trained through the S-212 course or an alternative chain saw course without completing the faller position task book appropriate to non-fire duties must limit their activities to Basic Faller standards and work under the supervision of an Intermediate Faller.

(ii) Employees trained through a Regionally-approved alternative non-fire chain saw course may be rated as a Basic Faller Trainee, Basic Faller, or an Intermediate Faller based on the instructor/evaluator’s recommendations, prior experience, task book completion, and as authorized by the Regional Safety Manager and Project Leader/Supervisor/Facility Manager by using and signing the FWS Form 3-2412, Chain Saw Operator Authorization Form (non-fire).

12.10 What are the general operational requirements for chain saw operators? Operators must:

A. Use chain saws only within their authorized faller classification (see Table 12-3),

B. Use chain saws within manufacturer’s specifications,

C. Maintain chain saws to the manufacturer’s specifications, and

D. Store and transport chain saws properly.

12.11 What are the requirements for instructors who teach the S-212 non-fire course?

A. Instructors must be certified by a State agency or vendor or meet the qualifications of an Intermediate Faller.

B. The Lead Instructor for the S‐212 course must be current as an Intermediate Faller or above. Unit or field instructors for the S‐212 course and alternatives to it must be technically proficient in the subject matter and cutting techniques described in the course.

C. Employees must have their position task books signed to verify that they’ve met the requirements and can safely perform the work. The person who signs the task book must be an operator who is proficient in the subject matter and cutting techniques described in the course and as follows:

(1) Individual task and final evaluation for a Basic Faller trainee must be verified or signed by a qualified Intermediate Faller or Advanced Faller (fire or non-fire).

(2) Individual task and final evaluation for an Intermediate Faller trainee must be verified or signed by a qualified Intermediate Faller or Advanced Faller (fire or non-fire).

(3) Individual task and final evaluation for an Advanced Faller trainee must be verified or signed by a qualified Advanced Faller (fire or non-fire).

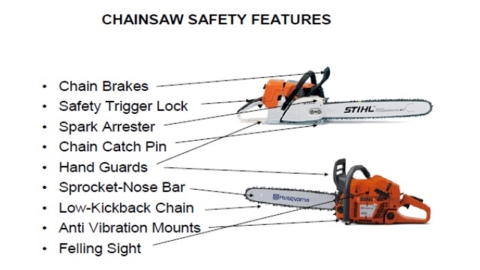

12.12 What are the equipment specifications for chain saws? Operators may only use chain saws that meet the following specifications (also see Figure 12-1):

A. Chain saws that are maintained in a serviceable condition.

B. Chain saws that meet the current ANSI Standard B175.1. If a saw does not meet these standards, the responsible Project Leader/Supervisor/Facility Manager must remove it from service.

C. Chain saws that comply with OSHA’s 29 CFR 1910.266 to include the following safety components:

(1) The Right Chains. Use the right chain for the job. Consider the complexity of the cut, the saw, and operator skill level (e.g., low kick-back chain for less experienced sawyers or skip-type chain for larger trees and more experienced sawyers).

(2) Chain Brakes. Test the chain breaks before each use. Apply chain brakes when you start the saw.

(3) Anti-Vibration Device(s). Consult the owner’s manual. All saws manufactured after 1991 should have this built into the saw.

(4) Safety Trigger Lock. This lock prevents the throttle from engaging unless a throttle interlock is depressed on the handle.

(5) Chain Catch Pin. This pin is on the underside of the saw below the base of the bar. It stops the chain from being expelled if the chain breaks.

(6) Spark Arrester. This device is on the exhaust system and reduces the fire hazard.

(7) Carrying Case or Chain Guard. Use either a case or a guard to transport and store the saw to protect you and others from injury.

(8) Hand Guards. These guards are on the throttle handle and chain saw guide handle (they may be incorporated with a chain brake).

Figure 12-1: Chain Saw Safety Features

D. Operations with felling and bucking equipment:

(1) Full Wrap-Around Handlebar. We recommend you use a full wrap-around handlebar for felling operations.

(2) Bumper Spikes (Dogs). You must use felling and bucking spikes (dogs) for moderately complex and highly complex (2 and 1) felling operations. We recommend using felling and bucking spikes for bucking operations.

12.13 What are the standards for PPE and its maintenance?

A. Project Leaders/Supervisors/Facility Managers must issue all required PPE to chain saw operators prior to chain saw use.

B. All PPE must be designed and constructed for the work you perform.

C. Your Project Leader/Supervisor/Facility Manager must:

(1) Complete a JHA for jobs that may require you to use non-standard PPE, and

(2) Purchase only PPE that meets ANSI, National Institute for Occupational Safety and Health (NIOSH), or equivalent industry standards for chain saw operations, and ensure it meets the standards when they receive it.

D. Either the operator or another designated employee must maintain all equipment in serviceable condition according to the manufacturers’ operating manuals and maintenance instructions. The operator must always inspect equipment before use during each work shift.

12.14 What PPE must operators use? Table 12-4 describes the required PPE and any other information essential to its use. Consult this table and the operator’s manual specific to the make and model of chain saw that will be used when developing a JHA for chain saw operations.

Table 12-4: Required PPE for Chain Saw Operation

| PPE | Required types | Other Essential Information |

|---|---|---|

| A. Hand protection | · Wear quality leather gloves consistent with weather conditions. · Do not use gauntlet-type gloves. · Wear anti-vibration (padded palm) gloves for long-duration cutting projects. | · We recommend cut-resistant Kevlar or ballistic nylon gloves for operators who use a chain saw frequently. |

| B. Eye and face protection* | · Wear ANSI Z87.1-approved eye protection (safety glasses or shield). | · We recommend wearing a logger type mesh screen attached to your helmet; safety glasses or goggles alone do not protect your face. · You can use clear shields, but they scratch easily and fog up in humid conditions. |

| C. Head protection* | · Wear ANSI Z89-approved type I, class “E” and “G” hard hat. · Inspect the hard hat before use and replace it according to the manufacturer’s specifications. | · The hard hat must display an annotation that it meets the ANSI standard. |

| D. Hearing protection* | · Wear ear plugs, ear muffs, or both. | · Properly fitted ear plugs provide the greatest level of noise reduction, and muffs can provide additional protection from cuts from brush. · Some saws operate at higher decibels, and if you operate the saw for extended periods, you may need to use double hearing protection. · Chain saw operation falls within the OSHA hearing loss prevention standards. See 242 FW 3 for information about noise level monitoring and audiometric testing. · Consult the Regional Safety Office for assistance. |

| E. Foot protection | · At a minimum, wear heavy duty leather or cut-resistant boots that: -Cover and support your ankles, · We recommend steel toed boots, but don’t require them because for some operations (working in extreme heat or cold), steel toed boots may not be prudent because they can transfer heat or cold to the foot. · If you do not wear safety boots because of the operation, your Project Leader/Supervisor/Facility Manager must write a JHA. The JHA must show that there are minimal hazards to the foot for this particular job, such as logs falling, and describe other precautions to use to reduce exposure. | · We recommend cut-resistant Kevlar or ballistic nylon logger boots for operators who use a chain saw frequently. These boots provide better protection from a direct strike of the chain. · Steel toed waders are available for working in water.Remember to clearly label them so they are not used for electrofishing. |

| F. Leg protection | · At a minimum, wear Service-provided cut-resistant logger chaps made with Kevlar or ballistic nylon. · Chaps must meet U.S. Forest Service Specification 6170-4F (Jan. 2000 or newer). The 6170-4F specification provides a higher level of protection or cut resistance of up to 3,200 feet per minute (fpm) chain speed. · The chaps must: -Cover the full length of the thigh, to 2 inches below the top of the boot, -Provide ¾ (leg front and side) coverage, and -Allow no gaps between the top of the boot and the chaps. | · Almost 50% of chain saw injuries occur to the legs. · Logger pants are also available for maximum protection. These pants provide better protection than the standard logger chaps and are more comfortable to wear in hot weather than the full coverage type chaps. WARNING: Additional operator caution is necessary when using an electric chain saw because chap fibers will not stop the higher constant torque. You must also consider electrocution hazards. |

*Logger type hard hats are available that offer sufficient eye, face, head, and hearing protection to meet these requirements. For ease of use, logger hard hats have built-in ear muffs and a mesh face-screen.

12.15 What other requirements do chain saw operators have to follow?

A. Risk Analysis. All chain saw operators, regardless of experience or qualifications, must thoroughly analyze tasks to determine if the level of risk is acceptable. If the level of risk is not acceptable, the operator must walk away. Operators should consider alternative solutions to risky operations, such as using heavy equipment, a contractor, or explosives. Also seek guidance from experienced sawyers.

B. Working Alone. All chain saw operators must work in a position or location that is within visual or audible contact with another employee/operator. Chain saw operators who must perform work alone that is not covered under the logging standard, such as incidental work to remove a single tree or limbs blocking a roadway passage, must:

(1) Be trained in evaluating complex bucking, sawing, and felling conditions and in hazardous tree operations;

(2) Have adequate radio or cell phone communications;

(3) Notify someone in a dispatch office, an administrative office, or on another part of the station of the situation and when work will begin; and

(4) Establish a check-in procedure for when the task is complete.

C. Observers and Spotters. No employee may approach a sawyer closer than 2½ times the height of the trees being felled until the sawyer acknowledges that it is safe to do so, unless a team of sawyers is necessary to fell a particular tree. The lead sawyer will determine if spotters are needed during tree-felling operations.

D. Escape Routes. These are predetermined paths of exit used by sawyers when felling or bucking. The essential components of an escape route are selection of the desired direction and distance prior to felling or bucking, and a well cleared path through which to escape. Sawyers must:

(1) Select and prepare the work area by clearing a primary escape path as well as a secondary (alternate) route before starting the cut;

(2) Be aware that the quadrant opposite the planned fall of the tree is extremely dangerous; and

(3) Choose an escape path that extends diagonally (45 degrees) away from the expected felling line, and always have an alternate retreat path to a safe zone.

E. Safe Zones. Sawyers must carefully plan the route from the stump to the safe zone. Safe zones should be no less than 20 feet from the stump. If possible, sawyers should stand behind another tree, preferably quartering back from the planned direction of the fall, and wait and watch at least 30 seconds after the tree hits the ground for whiplash branches and the scatter of broken tree parts.

F. Medical Availability. When chain saw operators are working in an area where medical assistance is not readily available (within 15-20 minutes), Project Leaders/Supervisors/Facility Managers must ensure a written plan exists for emergency response actions. The plan must include information about the nearest medical clinic and medical response capabilities.